Provincial Airways - Detailed Study of 3d air label.

Copyright

© 2022 Robert Farquharson All Rights Reserved

-

British Internal Airmails of the 1930’s

Section 2 - Production

Sheet Makeup

The makeup of the sheets is in vertical strips of four stamps with a margin on all four sides,

thus making an attractive miniature sheet. After being printed, gummed and perforated, the

sheets were made into pads of 5 sheets with a cardboard backing gummed along the top and

clamped together with a wire staple. Most of the sheets, therefore. show the holes in the top

margin where went through. Some survive. torn from the pads along the top line of

perforation resulting in them having margins on three sides only. Sheets from the first printing

were issued without being wired together. These have a wider margin at the top and bottom.

but this was trimmed off in later printings.

This is a used example of the pad with the last sheet remaining.

Production Method

From their appearance at first site, the stamps suggest production by Lithography, but this is not so

as they were printed by a typographical process. The two original dies, one for the framework value

and main design, and the other for the remainder of the stamp, were produced from the original

sketch by a photographic process by the Plymouth Process Engraving Company. Papier Mache

moulds were then taken from these, from which ordinary stereotypes were made by Messrs Clark

Doble and Co Ltd, the actual printers. Four of these stereotypes mounted on a block of wood

would then form the actual printing plate.

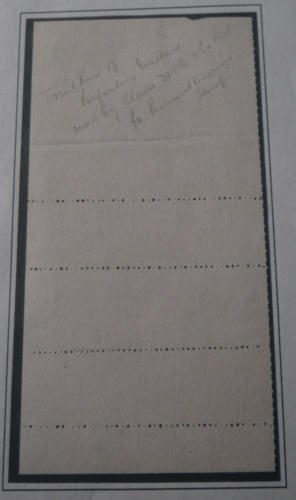

This imperforate proof sheet from the duty plate only is initialled by the designer M. C. Baugh.

This is an Imperforate proof sheet on gummed paper in the colours as issued

Perforating Method

The perforation was done by a treadle operated. single line, pin perforator gauging about 12;

this was the ordinary type of machine used for perforating carbon invoice books and similar

jobs and does not give a very clean cut effect.

A few sheets are known, mostly from the third printing, showing a double line of perforation

between the fourth stamp of the sheet and the lower margins.

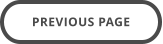

This example of the trial run of the perforating machine used by Messsrs Clark Doble. Notice

the roulletted edge on the right hand side.

Perforation Varieties

Second Supplementary Printing

The corner was doubled over before perforating.

Second Supplementary Printing

Third Printing

Double perforation lines at the base.

Provincial Airways - Detailed Study of 3d air label.

Copyright

© 2020 Robert Farquharson All Rights Reserved

British Internal Airmails of the 1930’s

Section 2 - Production

Sheet Makeup

The makeup of the sheets is in vertical strips of four stamps with a margin on all four sides,

thus making an attractive miniature sheet. After being printed, gummed and perforated, the

sheets were made into pads of 5 sheets with a cardboard backing gummed along the top and

clamped together with a wire staple. Most of the sheets, therefore. show the holes in the top

margin where went through. Some survive. torn from the pads along the top line of

perforation resulting in them having margins on three sides only. Sheets from the first printing

were issued without being wired together. These have a wider margin at the top and bottom.

but this was trimmed off in later printings.

This is a used example of the pad with the last sheet remaining.

Production Method

From their appearance at first site, the stamps suggest production by Lithography, but this is not so

as they were printed by a typographical process. The two original dies, one for the framework value

and main design, and the other for the remainder of the stamp, were produced from the original

sketch by a photographic process by the Plymouth Process Engraving Company. Papier Mache

moulds were then taken from these, from which ordinary stereotypes were made by Messrs Clark

Doble and Co Ltd, the actual printers. Four of these stereotypes mounted on a block of wood

would then form the actual printing plate.

This imperforate proof sheet from the duty plate only is initialled by the designer M. C. Baugh.

This is an Imperforate proof sheet on gummed paper in the colours as issued

Perforating Method

The perforation was done by a treadle operated. single line, pin perforator gauging about 12;

this was the ordinary type of machine used for perforating carbon invoice books and similar

jobs and does not give a very clean cut effect.

A few sheets are known, mostly from the third printing, showing a double line of perforation

between the fourth stamp of the sheet and the lower margins.

This example of the trial run of the perforating machine used by Messsrs Clark Doble. Notice

the roulletted edge on the right hand side.

Perforation Varieties

Second Supplementary Printing

The corner was doubled over before perforating.